A smooth new starter process and good day-to-day management of equipment are essential to the reputation and operation of all IT departments.

Traditionally, this is a never-ending cycle of standards, policies, delivery and backend information collection (CMDB). Frustrated users end up expensing high cost, non-standard equipment and building shadow IT solutions.

Determined to find a better way, we started a project with 3 aims:

With one person working on the process and another working on the system development, within 4 months we launched Juice. This case study presents our journey and results 12 months after launch, recognised by our Gold award in the Business Solutions category of the 2008 Intranet Innovation Awards.

High level standards were in place (e.g. Dell D630 laptop), but low level customisation was allowed (e.g. 4GB RAM instead of standard 2GB) leading to a wide range of parts and supported systems. With standards control and provision approval, ad-hoc decisions were continually required by IT as to what equipment should be supplied to individual users, for example, does this user do enough travel to justify a light-weight laptop? (Of course, in the end users work out to play the OH&S card and get what they want.)

Processes were designed for the best case (knowing weeks in advance about new starters), not the usual case (they start tomorrow). New equipment orders were placed as required, with a lead time of weeks to delivery and deployment. In addition, equipment was owned by and depreciated to individual cost centres throughout the business. This combination fostered a high level of ownership, but lead to protectionism, non-compliance, misallocation of costs and wasted resources as equipment sat in cupboards as departments tried to ensure a smooth entry for new starters.

This ad-hoc ownership and provision meant that broken equipment endured long downtime periods, particularly for remote users, as it was returned, fixed and then sent back. For new starters, equipment like PDA’s may even passed directly from ex-employees to new employees with no review, training or quality check.

Things worked before Juice, because everyone cared about the end user and worked hard to deliver. But, everyone was frustrated, spot fires were common and a lot of excess effort was required to make things run smoothly.

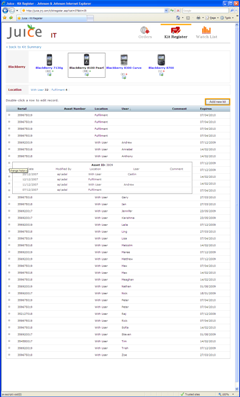

All equipment is now defined in kit form. For example: Dell D630 Laptop, BlackBerry 8100 Pearl, Lenovo 20” monitor docking station.

Each kit may have a number of accessories. For example: The Dell D630 Laptop includes a mouse, battery, carry bag, power pack and network cable. Whether they are new or previously used, shipped kits always include exactly those accessories. We chose to remove printed manuals, software CD’s, etc.

Lost or broken accessories may be individually replaced through single-click ordering. No approval is required as they are cheap and considered essential to the functioning of the kit. If a kit is returned incomplete, we simply charge the user for any missing accessories.

Each kit has a key item (e.g. the laptop itself). If that item is lost, stolen or broken then the entire kit is replaced. For example, we will send a completely new laptop kit including all accessories and ask for the old laptop / accessories to be returned. This ensures that we are always shipping kits complete and tested.

Where possible we use a “swap & repair” model to deal with problematic equipment and minimise downtime. For example, if a user is having trouble with their PDA we simply configure a new one and send it out immediately. The old PDA is then returned, repaired and reused in the future by another user.

This kit-based approach is highly flexible and allows the system to move beyond IT. We also track corporate credit cards, phone numbers and storage lockers as kits in Juice.

We decided that departments must control their own costs, while IT provides standards, service and guidance. If IT is a gatekeeper to individual needs and owns costs we’ll always be crushed by low level decisions, limiting the business with strict policies and eventually worked around through shadow IT or creative business / safety / any reasoning.

Instead, IT must control the standards, options and service. While users and managers must own the cost and have the freedom to make personal equipment choices.

As such, in Juice all equipment is purchased, owned and depreciated by the IT department. Based on the cost and useful life of each kit, they are leased to users at a fixed daily rate. This has a number of advantages:

If a kit is lost, broken or stolen the residual value is charged to the owner’s cost centre. While harsh in some cases, this provides encouragement to properly care for and safeguard equipment at all times.

If a user chooses to replace or upgrade a kit, they pay half the residual value of the kit they currently own. (This is a deterrent to upgrading early, but also discourages people from just reporting the kit as lost or broken.)

In the end, IT owns macro-level standards, cost control and service levels. Users own micro-level decisions, needs and cost-benefit choices.

New kits (e.g. I need a data projector), kit upgrades (e.g. I want a lightweight laptop), or kit replacements (e.g. I lost my PDA) require manager approval. This single step workflow is fast, effective and completed by the cost centre owner.

Replacement accessories do not require any approval, they are considered essential to keep the kit in good working order and charged immediately to your team cost centre. For transparency, these charges do appear in the managers monthly bill.

Users and managers have freedom, transparency and accountability for their purchase decisions and costs. IT has no involvement in these approval or workflow stages, we are not a gatekeeper. Our job is to maintain an appropriate menu of equipment, agree recommendations of standard kits per role and to provide high quality equipment, service and training.

Without good people control, you cannot have good asset or equipment control.

Juice synchronises each night with our HR system, detecting any additions, reductions or changes to the organisation structure. Juice also stores a position hierarchy for the business, including predefined employee types with standard equipment. We synchronise the HR changes with the position structure to create appropriate orders in the system.

As a result, we have no new starter forms for IT. This is a huge improvement from forms requesting accounts, ad-hoc requests for security access and equipment orders done on a person-by-person basis. For managers, the work has dramatically reduced. For new starters, the process is far more reliable.

Juice also stores cost centre and team information, inherited down through the organisational tree. With this information, Juice simplifies approvals and allocates charge backs.

A key insight during this project was the importance of separating

procurement (purchasing equipment) from fulfilment (distributing equipment).

In many cases, Juice is actually solving a fulfilment problem since equipment

is reused in the constant turn of employees.

The fulfilment team configures equipment, fulfils orders, checks returned equipment and orders new stock. This is a high touch process with considerable side activities to streamline the business. For example, we consider the redirection of phone numbers and the handing out of phones with a full battery charge to be a standard part of our service. The impact on users of this is remarkable – they can walk away with a phone that is immediately ready for business.

Separating fulfilment from procurement allows us to aim for a 2 business day turnaround on all orders. Kits are ready for immediate shipping and stock is ordered in batches using a simple two-bin Kanban system with visual cues. (Tracking stock levels in Juice is tempting, but much more complicated than visual cues.)

An order is only complete after the recipient marks it as received in Juice. This ensures that the delivery loop is closed and the user is satisfied.

Tracking kits in Juice gives us a full inventory of all equipment, along with its current owner and history of movement. This can be used for asset tracking, identifying troublesome equipment and timely upgrade of old equipment.

The first impression on new starters for IT and the business as a whole has been transformed. On their first day we can now hand them a computer, mobile phone, mobile broadband, etc all configured and in working order. This truly shows that we are an efficient, organised company who value your arrival and expect you to be productive. In feedback to HR, basic logistics has gone from the number one frustration of new users to the item they are most likely to raise as unprompted positive feedback.

For

managers, the new starter process now requires no forms and works well

regardless of the managers proactivity or experience in onboarding. This is a

huge relief and reduced burden on their time.

For day-to-day equipment purchases the adoption of Juice has been phenomenal. Within a year we’ve gone from no visibility or control of purchases to more than 180 orders being fulfilled each month. That’s 180 times each month that users can stay focused on their core job rather than worrying about equipment choices, shopping trips or doing nothing and remaining less productive.

Beyond the volume of orders, a great measure of success is the requests we’ve received to expand the catalogue into other areas. Not only did users as for data projectors to be added to the catalogue, but soon after we were asked to add a standard offering for data projector screens. High usability and simple ordering is actually driving users to request standard offerings!

For IT, Juice has increased our accountability through transparency, but it has also made it much easier for us to deliver high quality equipment on time. The process is clear, the orders are standard and our metrics are defined. Beyond that, and perhaps unexpectedly, we’ve also found the transparency has made our users more patient when we have stock delays or high demand. They can see their order is in the system and can trust that it won’t be missed or forgotten.

In

short, Juice increases both control and freedom. Users have the freedom to

choose which equipment best suits their needs, and control over their

individual costs. IT has control of equipment standards (the menu),

purchasing decisions and quality delivery.

The Juice model of ownership, approvals and cost control is highly extensible and flexible. We’ve continued to evolve the “kits” on offer and extend the system to cover non-IT aspects of our employees needs.

Juice is the database driving the people search capabilities on JCintra.

Juice is used for billing of consumable costs such as the SMS send feature of JCintra and our mobile broadband billing. In time, we will integrate per page costs for printer use and mobile phone charges.

We’re continuing to improve the processes around Juice, streamlining various activities. We automatically order name plates for head office staff and manage storage locker information for shipping of materials to field staff. In time, we will automate the ordering of things like business cards.

We will also continue to explore the capability of Juice to make other usually hidden information visible to end users. We imagine permissions and rights like signing authorities or system access controls tracked as visible assets in Juice - automatically triggering their setup for new users or revocation for leavers.

Juice was a low cost project that has had a large and growing impact on the day-to-day productivity of our business. The Clarify, Simplify, Implement approach pushed our team to convert our delivery process, remove the barriers for users and transform the financial model.

With Juice, users and manages have the freedom to choose the service mix they need, while IT controls the provision, standards and delivery of high quality equipment. Jobs are simpler, roles are clearer and we don’t need to fight for freedom or control.